A Guide to Best Practices in MedTech and Medical Devices Industry In the medical device and...

Best Practices for Field Inventory Control Within the Medical Devices Industry

In a fast-moving supply chain, small inefficiencies can have a big impact on overall performance. Industries such as the MedTech and Medical Devices where components have a high rate of obsolescence, are high value and also high impact in nature, this can pose a significant challenge. Small improvements in better control through digitisation and implementing best practises can have a massive impact on the bottom line, improve customer satisfaction while reduce component shelf time. An effective and efficient field inventory control is essential to ensure that you have the right components with the right quantities at the right place. This article will explain why field inventory control is essential to any MedTech business, common challenges faced and key best practices for improving your own process.

Take full advantage of digital solutions

Remote field inventory control is one of those processes that can seem like a constant balancing act. You want to remove the need for regular on-site inventories, which saves time and resources. Remote inventory control also gives MedTech companies greater visibility into their supply chain, allowing them to identify issues before they impact patient care or result in excess inventories. However, implementing remote inventory control also creates new challenges. The ability to monitor stock from a centralized system means your team cannot just rely on visual checks or barcodes when there’s an issue. You also must ensure your field team has the right tools to check inventories with minimal manual intervention and without increasing risk of error or theft. If you currently have a hybrid approach that combines on-site and remote inventory control, it’s time to implement fully remote processes and take full advantage of digital solutions available today. Here are some best practices for successful remote field inventory control.

Create a seamless remote inventory control process

The foundation of any remote inventory control process is having a clear understanding of what is in each location and when it should be replaced. There are key questions you must answer to ensure your remote inventory control process is successful:

- What items should be checked in each location and how often?

- What is the current inventory level at each location?

- Which items are running low or in danger of running out?

- Which items are stocked at the right levels?

- What items are at risk of expiring?

- What items need to be restocked now?

- Which items need to be restocked as soon as possible?

- What items need to be restocked at a certain point, but not right now?

Use data to identify risk

The best way to identify risk is to look at the data. You can start by analyzing your remote inventory control process. How often do your remote inventory checks fail? What percentage of the time do you have to manually restock items? What percentage of the time are your remote inventory locations out of stock? You can also use data from your other business systems to identify risk:

- Sales data: If certain products are frequently sold out in your remote inventory locations, there is a risk of customers walking away without buying.

- Customer support calls: If you have an increase in calls from customers who cannot find items in your remote inventory locations, this could indicate a risk that those items are out of stock.

- Field data: If you have an increase in remote inventory locations that are frequently out of stock, this could indicate risk that the items are frequently sold out.

- Production data: If certain materials are frequently out of stock in your remote inventory locations, this could indicate a risk to delivery schedules.

Automate your remote inventory control process

The best way to ensure your remote inventory control process is fully automated is to follow the process outlined above. There are several tools available that can automate most or all of your remote inventory control process. These tools can help you trigger restocking orders, send notifications, and track which remote inventory locations are out of stock. You can even integrate these tools with your shop floor systems to trigger replenishment orders, which will help you avoid running out of stock at remote inventory locations.

Automate manual processes and integrate with digital tools

While it’s important to automate as many manual processes as possible, there will always be a need for some manual actions and data entry. Some of the most common manual processes in remote inventory control are adding new inventory locations and entering new products. You can reduce the need for manual data entry by integrating with your supply chain management systems. You can also integrate with other systems and tools in your organization to make your remote inventory control process even more efficient. You can do this by using standard data types and even partnering with other vendors to create seamless integrations.

Use visibility tools to monitor supply chain issues

There are a few key visibility tools that can help you monitor supply chain issues. You can use analytics and business intelligence tools to monitor data. You can use lab testing and quality control tools to ensure your products meet quality standards. You can also use sensors and data visualization tools to monitor key supply chain metrics and identify potential issues before they impact your business. For example, remote barcode scanning systems can help you monitor inventory levels remotely. These systems can also help you ensure your field team is scanning products correctly and minimizing manual intervention. You can also use visibility tools to monitor the temperature of products in your supply chain. This can help you identify risk if your products are being exposed to extreme temperatures.

Provide the right tools to conduct remote inventory checks

The most important tools for your remote inventory team are the ones they use most frequently. You should equip your field team with mobile devices that have the functionality they need to conduct remote inventory checks. Ideally, these devices will also have long-lasting batteries, so your team can spend less time charging their devices. You can also consider providing your field team with devices that offer advanced imaging functionality. This can help your team take clear pictures of any issues they discover, which will help you to quickly address any problems.

Conclusion

Managing inventory remotely is an important step in creating more efficient operations. However, this process is also more challenging because it relies on data, not visual checks. By following these strategies, you can implement successful remote inventory control processes that improve inventory visibility, reduce errors and risk, and save time and money.

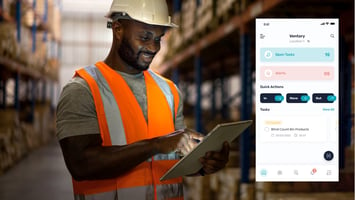

A software solution like Ventory becomes the smart extension into your core systems, so you can digitize your field inventory, wherever it is. With Ventory, you can increase liquidity, reduce wastage, improve efficiency, eliminate shrinkage, and ultimately improve your customer satisfaction.

Get in touch with our industry experts and discover how you can get started.