On-time and in-full (OTIF) delivery is crucial for maintaining customer satisfaction and ensuring...

Inventory Control: part of your Inventory Management Strategy

For most companies, inventory is one of their highest costs and ties up most working capital. Yet, research shows that around half of all SME businesses do not track their inventory - at all.

Inventory control is a key component of an effective inventory management process. Inventory or stock control ensures the right amount of supply is available in an organization. Activities include receiving, storing, and transferring inventory as well as tracking and fulfilling orders and returns. Here is an excellent guide on getting started.

Having the right materials available at the right time and in the right amounts to fulfill customer demands is important. You can determine which products you should use to fulfill customer demands by establishing the flow of inventory.

Inventory control can be accomplished in several ways, including:

FIFO (First in, First out) – using the oldest inventory first to fulfill customer orders.

LIFO (Last in, First out) – using the most recent inventory to fulfill customer orders.

FEFO (First expiring, First out) – using the inventory closest to its expiration date to fulfill customer orders

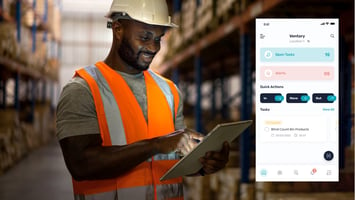

Warehouse organization is another aspect of inventory control. Upon its arrival, staff scan the product's barcode or RFID tag. Unique codes can be assigned per product type, or even to individual products.

The warehouse team checks the inbound shipments, fulfillment records and outbound orders.

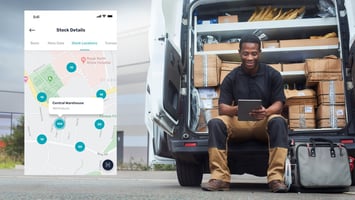

Vendor-managed inventory (VMI) sees the inventory on the premises of the vendor rather than the manufacturer/owner. The vendor decides when to refill orders and how much to send. This makes the visibility and data exchange between the parties even more important to have a reliable view on the state of the inventory.

Some of the fundamental elements of inventory control include:

- Placing and locating stock within a warehouse.

- Regularly monitoring stocks' condition, and ensuring it is used before its expiration date.

- Proactively following up on materials that need to be replaced or repaired before they can be delivered to the customer.

The benefits of inventory control include increased liquidity, reduced wastage, and retained customer loyalty. A smart extension to your existing systems, like Ventory, helps you digitize and reclaim control over your field inventory - wherever it is. With the best cycle counting solution on the market, Ventory is trusted by some of the world’s leading brands. Get in touch and discover how you can get started!