In today’s fast-paced business environment, it is important to have an effective inventory control...

How to Effectively Count Inventory Without Disrupting Warehouse Productivity

If you’re like most warehouse managers, you probably have a few nightmares about your quarterly, or yearly, inventory count.

The benefits of accurately counted inventory are indisputable. When you know exactly how much inventory you have on hand, you can better plan for future demand and avoid stockouts. Additionally, you can monitor your inventory turnover to ensure that you’re getting the maximum value out of your investment. For companies that use a just-in-time inventory management strategy, accurate counting is even more important because it ensures that the right amount of product is available at the appropriate time.

In short, when you don’t accurately count inventory, you risk having too much inventory or too little — both of which can impact your company’s bottom line. In short, inventory control is an integral part of your inventory management strategy.

Even though an accurate inventory count is a strategic business asset, many companies still organize their inventory count, or stocktake, on a quarterly or even yearly basis. A surprising number of companies rely on completely shutting down warehouse operations for the time being and taking inventory count, either by sending a team through the aisles to scan the inventory, or even noting stock levels by hand.

This approach greatly disrupts productivity. Everyone hates walking around with a clipboard counting things and marking shelves. Human error is inevitable, and records end up needing to be reconciled manually after the dreaded stocktake is over.

Fortunately, there are ways to effectively count inventory without disrupting your team’s workflow. Here are three strategies that will keep your team moving while maintaining accuracy and transparency of your inventory levels at the same time.

Manage Inventory Based on Count Data

One strategy for counting inventory is to calculate your inventory level based on the inventory counts from your last inventory taking. You can then track your inventory level throughout the month, and make corrections when necessary. This method is great for small businesses that don’t need to track inventory that closely. This inventory management method works well if you have a small business with a low-inventory count. You can manually count your inventory, write down the figure on a piece of paper, and write the date beside it. The following month, when it’s time to take another inventory, compare your current inventory count with your previous count and use the difference to calculate your current inventory level.

Run a (very) Partial Inventory Count, and Do It Often

Not counting inventory regularly is a big mistake, and it can lead to inaccurate inventory levels and increased shipping costs.

Another way to count inventory without disrupting your team is to run a partial inventory count whenever you can. This is the most cost-efficient approach because it doesn’t require any additional investment in time or money.

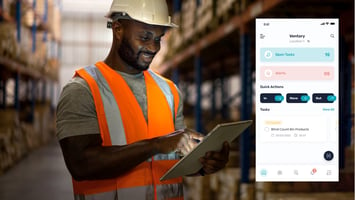

With a tool like Ventory, you can divide your inventory count into many small tasks, down to the individual bin level. Coworkers can do a single blind or cycle count in the minutes they have to spare before going on break or take on a couple of tasks subsequently when they have some downtime.

Do a Wall-to-Wall Count without Impacting Operations

One of the best ways to count inventory without disrupting your team is to use a computerized inventory counting system. Computerized inventory counting systems provide real-time inventory data that can be accessed anywhere. This allows managers to keep track of inventory levels and make updates as necessary. Computerized inventory counting systems are often installed in conjunction with warehouse barcode scanners. These devices scan items as they’re moved from one location to another. This data is then transmitted to the computerized inventory counting system, which automatically updates inventory levels.

A computerized inventory counting system also lets you keep an audit trail – ideal if items are recalled or if you need to be able to trace movements. Ventory helps you perform a wall to wall count without hindering your operations - your warehouse stays up and running while the counting activities are ongoing. Find out how Ventory can support your business.

Conclusion

Inventory accuracy is critical for any business, but it can be a real challenge for warehouse managers. Counting inventory can be time-consuming and stressful, which is why most warehouse managers try to avoid it as much as possible. Counting inventory doesn’t have to be a pain. Instead, it can be an efficient process that can be done in a matter of hours or even minutes. And it can be done without disrupting workflow or wasting valuable time.

Now that you know how to effectively count inventory without disrupting warehouse productivity, it’s time to put those skills to the test. The next time you’re scheduled to count inventory, try one of the strategies outlined above. Your team will thank you for it!